INDLELA YOKUSETYENZISWA KWESITOLO

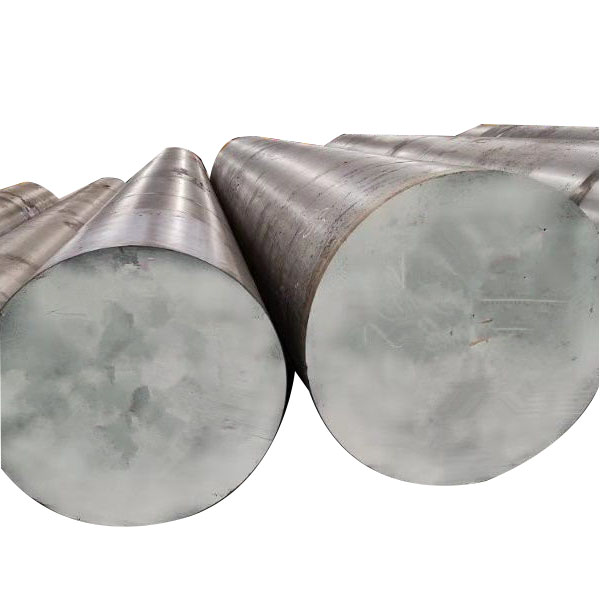

Hot Work Isixhobo Steel zakha bar Round

Isixhobo soMsebenzi eshushu sentsimbi ebhijelweyo

Hot Work Isixhobo Steel neeBhari Ulenze

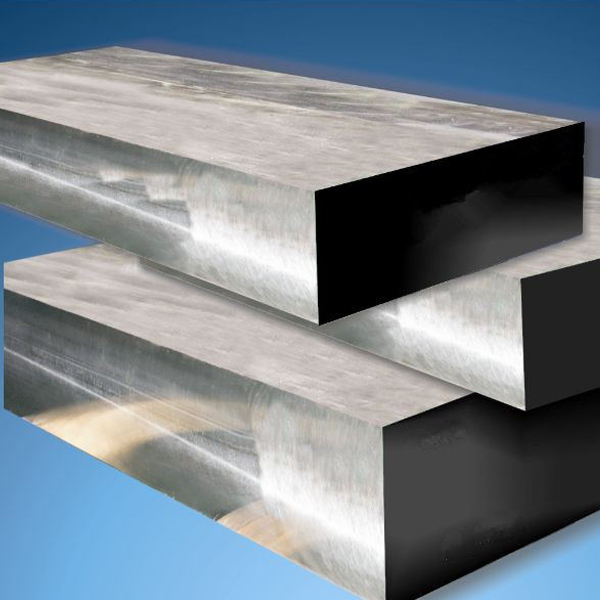

Isixhobo soMsebenzi eshushu seSinyithi esenziwe ngeBhloko

Ukusebenza kwemveliso

Isixhobo esisebenzayo seNsimbi sinezi zinto zilandelayo:

Ukuxhathisa kuTempering

Ukuchasana nomothuko wobushushu

Ukuphakama kwamandla obushushu

Ukuphakama kobushushu obuphezulu

Ukuphakama kobushushu kunxiba ukumelana

Umhlwa High -ukushisa nokumelana

Ukusebenza kwemveliso

Isixhobo esisebenza ngesinyithi sentsimbi, njengoko igama labo lisitsho, zisetyenziswa apho ukusebenza kwamaqondo esixhobo kunokufikelela kumanqanaba apho ukumelana nokuthamba, ukujonga ubushushu kunye nokothuka kubalulekile, Inokumelana nobushushu obuphezulu kunye nokumelana okuphakathi, ukugqwethwa kokuqina kuyacotha.

Eli qela lesinyithi lihle kakhulu ekusebenziseni okunje ngokufa, ukusweleka okuswelekileyo, ukubulawa kweplastikhi, iiDies eziQhelekileyo zokuSebenzisa, ukubamba okushushu kunye neeDies, ii-mandrels ezishushu, izibetho zomsebenzi oshushu kunye neemela ezishushu zokucheba

Ubukhulu becala UMSEBENZI OTSHISEKILEYO WENTSIMBI IBakala No.

| IMBALI |

GB (ETSHAYINA) |

DIN |

I-ASTM |

JIS |

| HSH 13 | 4Cr5MoSiV1 | 1.2344 | H13 | I-SKD61 |

| HSH11 | 4Cr5MoSiV | 1.2343 | H11 | I-SKD6 |

| HSH12 | 4Cr5MoWSiV | 1.2606 | H12 | I-SKD62 |

| HSH10 | 4Cr3Mo3SiV | 1.2365 | H10 | SKD7 |

| HSH21 | 3Cr2W8V | 1.2581 | H21 | I-SKD5 |

| HSH6 | 5CrNiMo | 1.2714 | L6 |

UKWENZIWA KWEMICIMBI

|

IMBALI |

DIN |

I-ASTM |

UKWENZIWA KWEMICIMBI |

IPROPATI |

ISICELO |

||||||||

|

C |

Hayi |

Mnu |

P≤ |

S≤ |

Kr |

Mo |

V |

UW |

|||||

|

HSH13 |

1.2344 |

H13 |

0.35-0.42 |

0.80-1.20 |

0.25-0.50 |

0.030 |

0.030 |

4.80-5.50 |

1.20-1.50 |

0.85-1.15 |

- |

Ukuqina okuphezulu, ukumelana nokunxiba okuhle kunye nobushushu obushushu. inokumelana okuhle kukothuka, (i-ESR) i-H13 ine-homogeneity enkulu kunye nolwakhiwo oluhle kakhulu, olukhokelela ekuphuculweni kokusebenza, ukupolisha kunye namandla aphezulu obushushu. |

Uxinzelelo lokufa izixhobo zokuphosa, i-extrusion die, i-forging die, i-blade ye-shear eshushu, i-stamping die, i-plastic molds, i-mandrels yomsebenzi oshushu, i-ESR H13 ilungile kwizixhobo zokuphosa i-aluminium kunye nezixhobo zokubumba zeplastiki ezifuna ipolishi ephezulu kakhulu. |

|

HSH12 |

1.2606 |

H12 |

0.32-0.40 |

0.90-1.20 |

0.30-0.60 |

0.030 |

0.030 |

5.00-5.60 |

1.30-1.60 |

0.15-0.40 |

1.20-1.40 |

Ukuqaqamba kwempembelelo egqwesileyo. Umxholo we-tungsten ubonelela ngokunganyangekiyo komoya ophucukileyo, ukuqina okunzulu, isinyithi esomisa umoya esibonisa utshintsho kubungakanani obuncinci ngexesha lonyango lobushushu. Ukumelana elungileyo ukudinwa thermal nokuqhekeka |

inqindi eshushu, afe bephosa kufa, ekwenziweni uyafa, iincakuba ezishushu uchebe, gripper eshushu uyafa, kwaye extrusion uyafa. |

|

YTR50 |

1.2343 |

H11 |

0.33-0.41 |

0.80-1.20 |

0.25-0.50 |

0.030 |

0.030 |

4.80-5.50 |

1.10-1.50 |

0.30-0.50 |

- |

Ukuqina High, ubulukhuni egqwesileyo, ukumelana elungileyo kukothuka thermal xa amanzi lupholile kwinkonzo, utshintsho ubungakanani ubuncinane ngexesha unyango ubushushu. |

Kunconywe usetyenziso lwezixhobo ezishushu apho kufuneka khona ukuxhathisa okuphezulu ekuqhekekeni. Iinqindi ezishushu, kufa ukulahla kufa, ukwenza okokufa, ukutshisa okushushu, i-gripper eshushu iyafa, i-extrusion iyafa. |

|

HSH10 |

1.2365 |

H10 |

0.28-0.35 |

0.10-0.40 |

0.15-0.45 |

0.030 |

0.030 |

2.70-3.20 |

2.50-3.00 |

0.40-70 |

- |

Ukumelana Zintle ukuthamba kwiqondo lobushushu eliphezulu. ukumelana kakhulu nokukhathala kokukhathala kobushushu, kwaye kunokupholisa amanzi kwinkonzo |

Izixhobo ezinzima zokuphosa izixhobo zentsimbi, ukugqobhoza iiMandrels, ukubetha okushushu, ukwenza i-die, i-shears ezishushu |

|

HSH21 |

1.2581 |

H21 |

0.25-0.35 |

0.10-0.40 |

0.15-0.45 |

0.030 |

0.030 |

2.50-3.20 |

- |

0.30-0.50 |

8.50-9.50 |

Ibonisa ukumelana okugqwesileyo ekuthobeni kubushushu obuphezulu. Akufuneki apholiswe ngamanzi kwinkonzo ngaphandle kokuba isixhobo sibandakanya ukuhamba okuqhubekayo kokupholisa amanzi kwangaphakathi. Ukutshatyalaliswa kwe-thermal kufuneka kugwenywe |

Kunconywe ukuba kusetyenziswe izixhobo ezinzima zomsebenzi wesinyithi ezinje ngobhedu extrusion, ubhedu ufe umlingisi, iipunch ezishushu, ukufaka ii-die ins. |

|

HSH6 |

1.2714 |

L6 |

0.50-0.60 |

0.10-0.40 |

0.60-0.90 |

0.030 |

0.030 |

0.80-1.20 |

0.35-0.55 |

0.05-0.15 |

Ni 1.50-1.80 |

Ubungqongqo impembelelo High kunye nokumelana elungileyo ukuthamba kwiqondo lobushushu eliphezulu. ukumelana elungileyo ukothuka thermal kunye nokudinwa yokuqhekeza thermal, utshintsho oluncinci ntathu ngexesha lukhuni. |

Die ekwakheni, afe eyahlulayo, extrusion, iglasi processing,. Mandrels, Abanini bokufa |

Ubukhulu becala Isixhobo soMsebenzi esiBandayo ngeBanga lesi-3.

|

IMVELISO |

IMEKO YOKUNIKEZELWA KWEENKONZO NEENKQUBO EZIFUMANEKAYO |

|||

|

IBAR YOKUQALA |

UKUDWALWA KWEBANDELA |

UMHLABA ONGAPHAKATHI |

I-PEELED |

IJIKILE |

|

ULAWULO KWI-MM |

2.5-12.0 |

8.5-16 |

16-75 |

Ngama-75-610 |

|

SQUARE |

IHOTI IJIKA UMNYAMA |

BAKHOHLISA LONKE ICANDELO LITSIBILE |

||

|

SIZE KWIMM |

6X6-50X50 |

55X55-510X510 |

||

|

IFLEYI YEBHALA |

IHOTI IJIKA UMNYAMA |

BAKHOHLISA LONKE ICANDELO LITSIBILE |

||

|

Ububanzi X X ububanzi MM |

3-40 X 12-610 |

80-405 X 100-810 |

||

|

IDISKI |

I-350-800MM DIA X80-400 ENTSHA |

|||